Advancing Climate Solutions Report

Jan. 8, 2024

Advancing Climate Solutions Report

Jan. 8, 2024

Jan. 8, 2024

Our Enterprise Risk Management Framework provides a comprehensive and structured approach to identify, prioritize, understand, and manage ExxonMobil’s most important risks. It is designed to drive consistency across risk types and support monitoring key risks. For more details on the risks we consider and manage, refer to Item 1A. Risk Factors in the 10-K.

Managing long-term risks associated with climate change and the energy transition is a key part of managing a broad spectrum of interrelated risks.

Our enterprise risk framework includes five elements:

Our approach to risk governance is multilayered and includes clearly defined roles and responsibilities for managing each type of risk. It includes a definition of the responsibilities of risk owners, functional experts, and independent verifiers. Each risk type is managed and supported by organizations that actively execute risk management processes and are responsible for specifying corporate requirements and processes. Each of these processes includes the critical elements of leadership, people, risk identification and management, and continuous improvement. Oversight responsibilities by the Management Committee and the Board and its committees are a key part of risk governance. Our Management Committee consists of our Chief Executive Officer, our Chief Financial Officer, and our two Senior Vice Presidents.

We have extensive experience operating in a wide range of challenging physical environments around the world.

Effective risk management requires the ongoing assessment and mitigation of potential impacts to our people, our assets, the community, and the environments in which we operate. Before pursuing a new development, we use data and advanced computer modeling to assess the full range of potential environmental, socioeconomic and health risks associated with potential construction and operations. We also consult with communities through public meetings and other outreach, and we work with regulators to share information and seek necessary approvals. This process gives us a comprehensive understanding of possible impacts, which we use to implement measures to avoid, reduce, or remedy environmental, socioeconomic, and health risks or impacts.

When considering physical environmental risks, we evaluate the type and location of facilities and investments. As an example, changes in patterns of waves, wind, or ice floes can affect offshore facilities. Onshore facilities could be vulnerable to sea level rise, changes in storm surge, flooding, changes in wind and seismic activity, or geo-technical considerations. We conduct environmental assessments before building and operating facilities to ensure that protective measures and procedures are in place.

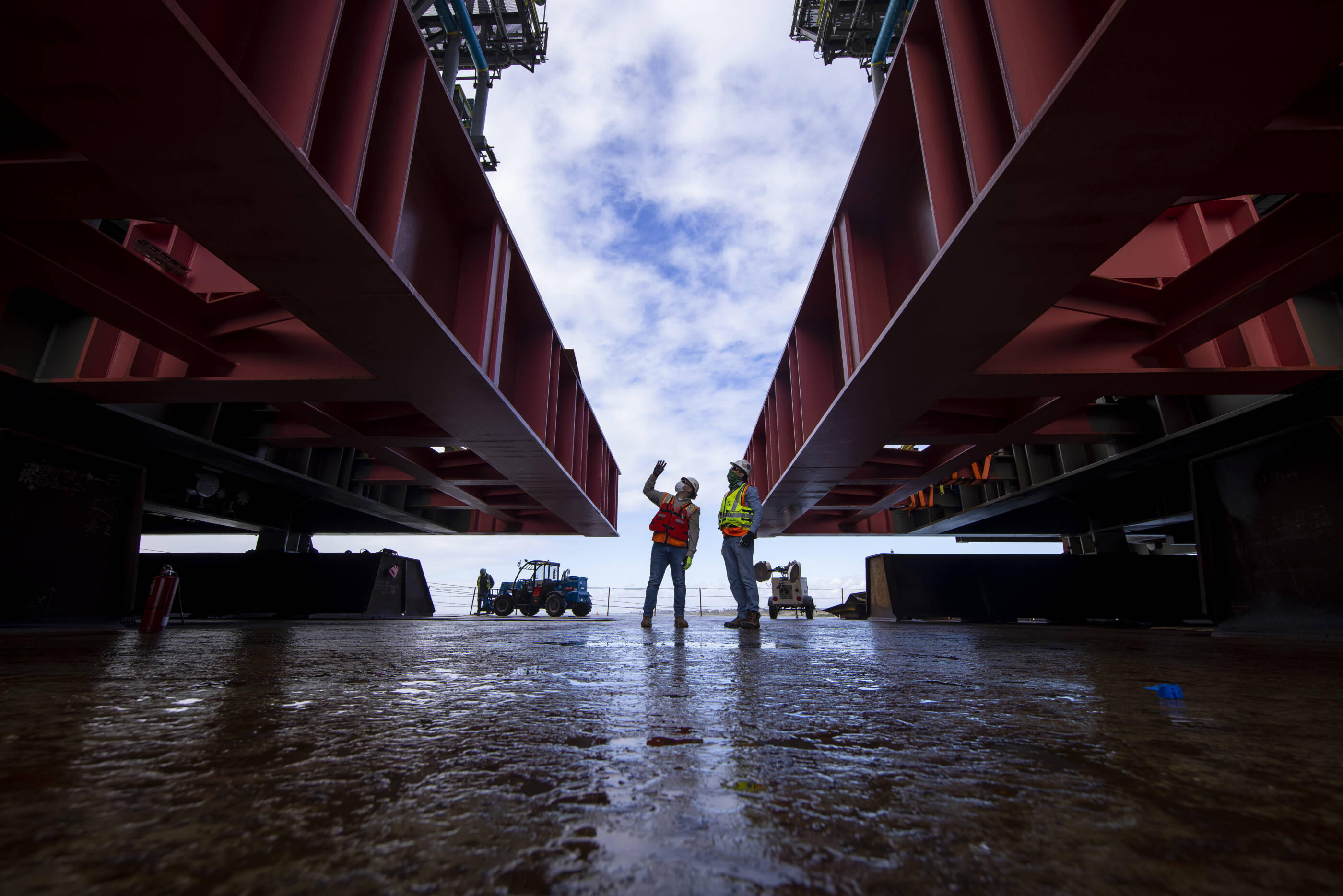

Hebron

.jpg)

The Hebron platform is located off the coast of eastern Canada in 92 meters of water. The platform is a reinforced concrete gravity-based structure designed to withstand sea ice, icebergs, and meteorological and oceanographic conditions. Hebron was engineered and wave-tank tested for storms so extreme they may occur only once every 10,000 years. On Nov. 14, 2018, the Grand Banks saw its largest storm in 30 years, estimated as a 100-year return period event. Following temporary shutdown of all Grand Banks platforms, Hebron was up and running within a week without any major issues.

Our scientists and engineers are industry experts across a variety of disciplines. Through their active participation and leadership in industry groups, they advise and gather insights to inform and improve industry standards which, in turn, are adopted to enhance our standards and procedures. We follow industry practices such as the American Society of Civil Engineers’ Climate Resilient Infrastructure: Adaptive Design and Risk Management manual of practice.1

Industry standards, including American Society of Civil Engineers (ASCE 7)2 Minimum Design Loads and Associated Criteria for Buildings and Other Structures, are also used along with professional experience to cover a range of uncertainties. After construction of a facility, we monitor and manage ongoing facility integrity through periodic checks of key aspects of the structures.

The Gulf Coast Growth Venture, a petrochemical manufacturing facility near Corpus Christi, Texas, is compliant with both San Patricio County and national standards (ASCE 7). Stormwater handling is a risk factor associated with the facility, so the design includes basins to retain excess stormwater to supplement the capacity of the municipal water system. The design, construction, and operations of petrochemical facilities are highly regulated by the Texas Commission on Environmental Quality.

Company representatives held hundreds of outreach meetings with local organizations, chambers, government agencies, civic groups, and neighborhoods and have addressed comments and concerns raised during the permitting process. More information on the Texas Commission on Environmental Quality permitting process can be found on its website.3

Once facilities are in operation, we maintain disaster preparedness, response, and business continuity plans. Detailed, well-practiced, and continuously improved emergency response plans are tailored to each facility to help us prepare for unplanned events, including extreme weather. Periodic emergency drills are conducted with appropriate government agencies and community coalitions to help heighten readiness and minimize the impacts of an event. Strategic emergency support groups are established around the world to develop and practice emergency response strategies and assist field responders. Regardless of the size or complexity of any potential incident, each ExxonMobil facility and business unit has access to readily available trained responders, including regional response teams, to provide rapid tactical support.

FOOTNOTES:

FORWARD-LOOKING STATEMENT WARNING

CAUTIONARY STATEMENT RELEVANT TO FORWARD LOOKING INFORMATION FOR THE PURPOSE OF THE “SAFE HARBOR” PROVISIONS OF THE PRIVATE SECURITIES LITIGATION REFORM ACT OF 1995 AND OTHER IMPORTANT LEGAL DISCLAIMERS

Images or statements of future ambitions, plans, goals, events, projects, projections, opportunities, or conditions in the publications, including plans to reduce, abate, avoid or enable avoidance of emissions or reduce emissions intensity, sensitivity analyses, expectations, estimates, the development of future technologies, business plans, and sustainability efforts are dependent on future market factors, such as customer demand, continued technological progress, policy support and timely rule-making or continuation of government incentives and funding, and represent forward-looking statements. Similarly, emission-reduction roadmaps to drive toward net zero and similar roadmaps for emerging technologies and markets, and water management roadmaps to reduce freshwater intake and/or manage disposal, are forward-looking statements. These statements are not guarantees of future corporate, market or industry performance or outcomes for society and are subject to numerous risks and uncertainties, many of which are beyond our control or are even unknown.

Actual future results, including the achievement of ambitions to reach Scope 1 and 2 net zero from operated assets by 2050, to reach Scope 1 and 2 net zero in Upstream Permian Basin unconventional operated assets by 2030, to eliminate routine flaring in-line with World Bank Zero Routine Flaring, to reach near zero methane emissions from operated assets and other methane initiatives, to meet greenhouse gas emission reduction plans or goals, divestment and start-up plans, and associated project plans; technology advances including in the timing and outcome of projects to capture and store CO2 supply lower-emission fuels, produce hydrogen, produce lithium, obtain data on detection, measurement and quantification of emissions including reporting of that data or updates to previous estimates, and use plastic waste as feedstock for advanced recycling; progress in sustainability focus areas; and reserve or resource changes could vary depending on changes in supply and demand and other market factors affecting future prices of oil, gas, petrochemical or new market products and services; future cash flows; our ability to execute operational objectives on a timely and successful basis; policy and consumer support for emission-reduction and other advanced products and technology; changes in international treaties, laws, regulations and incentives, including those greenhouse gas emissions, plastics, carbon storage and carbon costs; evolving reporting standards for these topics and evolving measurement standards for reported data; trade patterns and the development and enforcement of local, national and regional mandates; unforeseen technical or operational difficulties; the outcome of research efforts and future technology developments, including the ability to scale projects and technologies such as electrification of operations, advanced recycling, CCS, hydrogen production, or direct lithium extraction on a commercially competitive basis; availability of feedstocks for lower-emission fuels, hydrogen, or advanced recycling; changes in the relative energy mix across activities and geographies; the actions of competitors; changes in regional and global economic growth rates and consumer preferences; actions taken by governments and consumers resulting from a pandemic; changes in population growth, economic development or migration patterns; military build-ups, armed conflicts, or terrorism; and other factors discussed in this release and in Item 1A. “Risk Factors” in ExxonMobil’s Annual Report on Form 10-K for 2022 and subsequent Quarterly Reports on Forms 10-Q, as well as under the heading “Factors Affecting Future Results” on the Investors page of ExxonMobil’s website at www.exxonmobil.com. The Advancing Climate Solutions Report includes 2022 greenhouse gas emissions performance data and Scope 3 Category 11 estimates for full-year 2022 as of March 1, 2023. The greenhouse gas intensity and greenhouse gas emission estimates include Scope 2 market-based emissions. The Sustainability Report, the Advancing Climate Solutions Report, and corresponding Executive Summaries were issued on Jan. 8, 2024. The content and data referenced in these publications focus primarily on our operations from Jan. 1, 2022 – Dec. 31, 2022, unless otherwise indicated. Information regarding some known events or activities in 2023 are also included. No party should place undue reliance on these forward-looking statements, which speak only as of the dates of these publications. All forward-looking statements are based on management’s knowledge and reasonable expectations at the time of publication. We do not undertake to provide any further updates or changes to any data or forward-looking statements in these publications. Neither future distribution of this material nor the continued availability of this material in archive form on our website should be deemed to constitute an update or re-affirmation of these figures or statements as of any future date. Any future update will be provided only through a public disclosure indicating that fact.

ABOUT THE ADVANCING CLIMATE SOLUTIONS AND SUSTAINABILITY REPORTS

The Advancing Climate Solutions Report contains terms used by the TCFD, as well as information about how the disclosures in this report are consistent with the recommendations of the TCFD. In doing so, ExxonMobil is not obligating itself to use any terms in the way defined by the TCFD or any other party, nor is it obligating itself to comply with any specific recommendation of the TCFD or to provide any specific disclosure. For example, with respect to the term “material,” individual companies are best suited to determine what information is material, under the long-standing U.S. Supreme Court definition, and whether to include this information in U.S. Securities and Exchange Act filings. In addition, the ISSB is evaluating standards that provide their interpretation of TCFD which may or may not be consistent with the current TCFD recommendations.

These publications have been prepared at shareholders’ request or for their convenience and intentionally focused on unknown future events that we have been asked to consider. Forward-looking and other statements regarding environmental and other sustainability efforts and aspirations are not intended to communicate any material investment information under the laws of the United States or represent that these are required disclosures. These publications are not intended to imply that ExxonMobil has access to any significant non-public insights on future events that the reader could not independently research. In addition, historical, current, and forward-looking environmental and other sustainability-related statements may be based on standards for measuring progress that are still developing, internal controls and processes that continue to evolve, and assumptions that are subject to change in the future, including future laws and rulemaking. Forward-looking and other statements regarding environmental and other sustainability efforts and aspirations are for informational purposes only and are not intended as an advertisement for ExxonMobil’s equity, debt, businesses, products, or services and the reader is specifically notified that any investor-requested disclosure or future required disclosure is not and should not be construed as an inducement for the reader to purchase any product or services. The statements and analysis in these publications represent a good faith effort by the Company to address these investor requests despite significant unknown variables and, at times, inconsistent market data, government policy signals, and calculation, methodologies, or reporting standards.

Actions needed to advance ExxonMobil’s 2030 greenhouse gas emission-reductions plans are incorporated into its medium-term business plans, which are updated annually. The reference case for planning beyond 2030 is based on the Company’s Global Outlook research and publication. The Global Outlook is reflective of the existing global policy environment and an assumption of increasing policy stringency and technology improvement to 2050. However, the Global Outlook does not attempt to project the degree of required future policy and technology advancement and deployment for the world, or ExxonMobil, to meet net zero by 2050. As future policies and technology advancements emerge, they will be incorporated into the GIobal Outlook, and the Company’s business plans will be updated as appropriate. References to projects or opportunities may not reflect investment decisions made by the corporation or its affiliates. Individual projects or opportunities may advance based on a number of factors, including availability of supportive policy, permitting, technological advancement for cost-effective abatement, insights from the company planning process, and alignment with our partners and other stakeholders. Capital investment guidance in lower-emission investments is based on our corporate plan; however, actual investment levels will be subject to the availability of the opportunity set, public policy support, other factors, and focused on returns.

Energy demand modeling aims to replicate system dynamics of the global energy system, requiring simplifications. The reference to any scenario or any pathway for an energy transition, including any potential net-zero scenario, does not imply ExxonMobil views any particular scenario as likely to occur. In addition, energy demand scenarios require assumptions on a variety of parameters. As such, the outcome of any given scenario using an energy demand model comes with a high degree of uncertainty. For example, the IEA describes its NZE scenario as extremely challenging, requiring unprecedented innovation, unprecedented international cooperation, and sustained support and participation from consumers, with steeper reductions required each year since the scenario’s initial release. Third-party scenarios discussed in these reports reflect the modeling assumptions and outputs of their respective authors, not ExxonMobil, and their use or inclusion herein is not an endorsement by ExxonMobil of their underlying assumptions, likelihood, or probability. Investment decisions are made on the basis of ExxonMobil’s separate planning process but may be secondarily tested for robustness or resiliency against different assumptions, including against various scenarios. These reports contain information from third parties. ExxonMobil makes no representation or warranty as to the third-party information. Where necessary, ExxonMobil received permission to cite third-party sources, but the information and data remain under the control and direction of the third parties. ExxonMobil has also provided links in this report to third-party websites for ease of reference. ExxonMobil’s use of the third-party content is not an endorsement or adoption of such information.

ExxonMobil reported emissions, including reductions and avoidance performance data, are based on a combination of measured and estimated data. We assess our performance to support continuous improvement throughout the organization using our Environmental Performance Indicator (EPI) process. The reporting guidelines and indicators in the Ipieca, the American Petroleum Institute (API), the International Association of Oil and Gas Producers Sustainability Reporting Guidance for the Oil and Gas Industry (4th edition, 2020, revised February 2023) and key chapters of the GHG Protocol inform the EPI process and the selection of the data reported. Emissions reported are estimates only, and performance data depends on variations in processes and operations, the availability of sufficient data, the quality of those data and methodology used for measurement and estimation. Emissions data is subject to change as methods, data quality, and technology improvements occur, and changes to performance data may be updated. Emissions, reductions, abatements and enabled avoidance estimates for non-ExxonMobil operated facilities are included in the equity data and similarly may be updated as changes in the performance data are reported. ExxonMobil’s plans to reduce emissions are good-faith efforts based on current relevant data and methodology, which could be changed or refined. ExxonMobil works to continuously improve its approach to identifying, measuring, and addressing emissions. ExxonMobil actively engages with industry, including API and Ipieca, to improve emission factors and methodologies, including measurements and estimates.

Any reference to ExxonMobil’s support of, work with, or collaboration with a third-party organization within these publications do not constitute or imply an endorsement by ExxonMobil of any or all of the positions or activities of such organization. ExxonMobil participates, along with other companies, institutes, universities and other organizations, in various initiatives, campaigns, projects, groups, trade organizations, and other collaborations among industry and through organizations like the United Nations that express various ambitions, aspirations and goals related to climate change, emissions, sustainability, and the energy transition. ExxonMobil’s participation or membership in such collaborations is not a promise or guarantee that ExxonMobil’s individual ambitions, future performance or policies will align with the collective ambitions of the organizations or the individual ambitions of other participants, all of which are subject to a variety of uncertainties and other factors, many of which may be beyond ExxonMobil’s control, including government regulation, availability and cost-effectiveness of technologies, and market forces and other risks and uncertainties. Such third parties’ statements of collaborative or individual ambitions and goals frequently diverge from ExxonMobil’s own ambitions, plans, goals, and commitments. ExxonMobil will continue to make independent decisions regarding the operation of its business, including its climate-related and sustainability-related ambitions, plans, goals, commitments, and investments. ExxonMobil’s future ambitions, goals and commitments reflect ExxonMobil’s current plans, and ExxonMobil may unilaterally change them for various reasons, including adoption of new reporting standards or practices, market conditions; changes in its portfolio; and financial, operational, regulatory, reputational, legal and other factors.

References to “resources,” “resource base,” “recoverable resources” and similar terms refer to the total remaining estimated quantities of oil and natural gas that are expected to be ultimately recoverable. The resource base includes quantities of oil and natural gas classified as proved reserves, as well as quantities that are not yet classified as proved reserves, but that are expected to be ultimately recoverable. The term “resource base” is not intended to correspond to SEC definitions such as “probable” or “possible” reserves. For additional information, see the “Frequently Used Terms” on the Investors page of the Company’s website at www.exxonmobil.com under the header “Resources.” References to “oil” and “gas” include crude, natural gas liquids, bitumen, synthetic oil, and natural gas. The term “project” as used in these publications can refer to a variety of different activities and does not necessarily have the same meaning as in any government payment transparency reports.

Exxon Mobil Corporation has numerous affiliates, many with names that include ExxonMobil, Exxon, Mobil, Esso, and XTO. For convenience and simplicity, those terms and terms such as “Corporation,” “company,” “our,” “we,” and “its” are sometimes used as abbreviated references to one or more specific affiliates or affiliate groups. Abbreviated references describing global or regional operational organizations, and global or regional business lines are also sometimes used for convenience and simplicity. Nothing contained herein is intended to override the corporate separateness of affiliated companies. Exxon Mobil Corporation’s goals do not guarantee any action or future performance by its affiliates or Exxon Mobil Corporation’s responsibility for those affiliates’ actions and future performance, each affiliate of which manages its own affairs. For convenience and simplicity, words like venture, joint venture, partnership, co-venturer and partner are used to indicate business relationships involving common activities and interests, and those words may not indicate precise legal relationships. These publications cover Exxon Mobil Corporation’s owned and operated businesses and do not address the performance or operations of our suppliers, contractors or partners unless otherwise noted. In the case of certain joint ventures for which ExxonMobil is the operator, we often exercise influence but not control. Thus, the governance, processes, management and strategy of these joint ventures may differ from those in these reports. At the time of publication, ExxonMobil has completed the acquisition of Denbury Inc. and is in the process of acquiring Pioneer Natural Resources. These reports do not speak of these companies’ historic governance, risk management, strategy approaches or emissions performance unless specifically referenced.

These reports or any material therein is not to be used or reproduced without the permission of Exxon Mobil Corporation. All rights reserved.

SUPPLEMENTAL INFORMATION FOR NON-GAAP AND OTHER MEASURES

The Resiliency section of the Advancing Climate Solutions Report mentions modeled operating cash flow in comparing different businesses over time in a future scenario. Historic operating cash flow is defined as net income, plus depreciation, depletion and amortization for consolidated and equity companies, plus noncash adjustments related to asset retirement obligations plus proceeds from asset sales. The Company’s long-term portfolio modeling estimates operating cash flow as revenue or margins less cash expenses, taxes and abandonment expenditures plus proceeds from asset sales before portfolio capital expenditures. The Company believes this measure can be helpful in assessing the resiliency of the business to generate cash from different potential future markets. The performance data presented in the Advancing Climate Solutions Report and Sustainability Report, including on emissions, is not financial data and is not GAAP data.